BOS Technology GmbH has established itself worldwide as a professional and dependable partner for the automation of production processes. One of our greatest strengths is the flexible and customised development and composition of standardised modules to create powerful specialized machines.

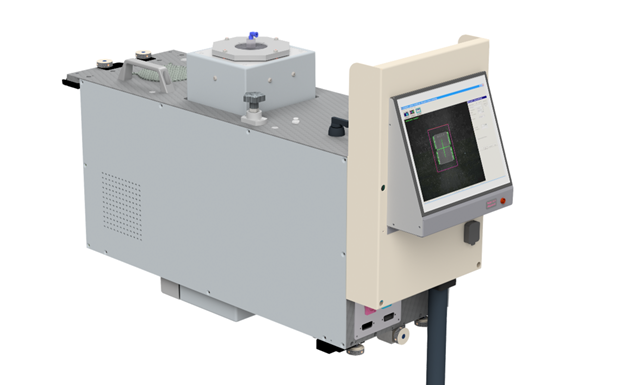

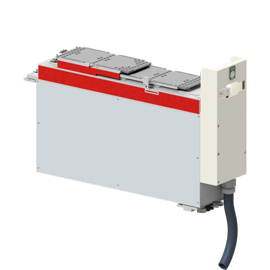

With totally reliable optical and electrical measurement, the ARENA, AT∅M, DESKTOP und UNIMX series deliver 100% quality control.

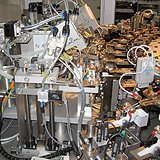

Flexible & customised automation system

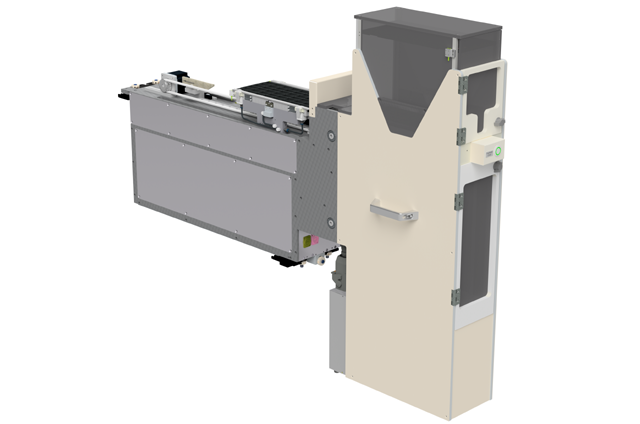

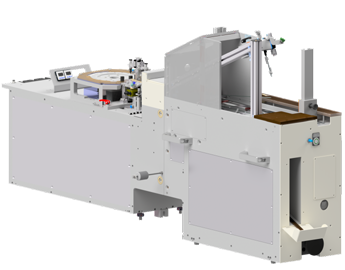

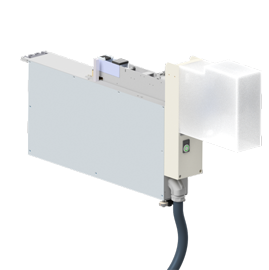

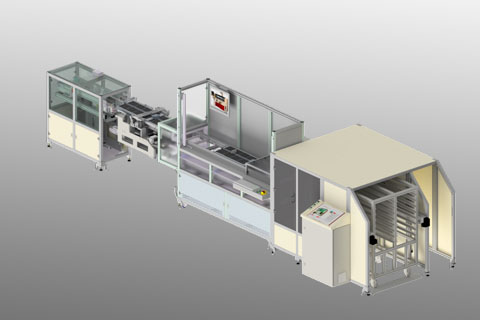

Flexible, customised and economical thanks to tried-and-tested standards. With the fully automated system, electronic components can be checked and packaged quickly and reliably.

Very flexible, customised

We specialise in the development and production of equipment for the back-end sector of the semiconductor industry, such as checking equipment, tape and reel machines and programming equipment. With our own production facilities, we are able to accommodate customers' wishes quickly and with tremendous flexibility.

BOS develops and builds equipment and complex automated solutions for manufacturers of medicine and medical technology. With the continuous move towards miniaturisation, the challenge is now to automatically mount ever smaller individual components for assemblies or finished products.

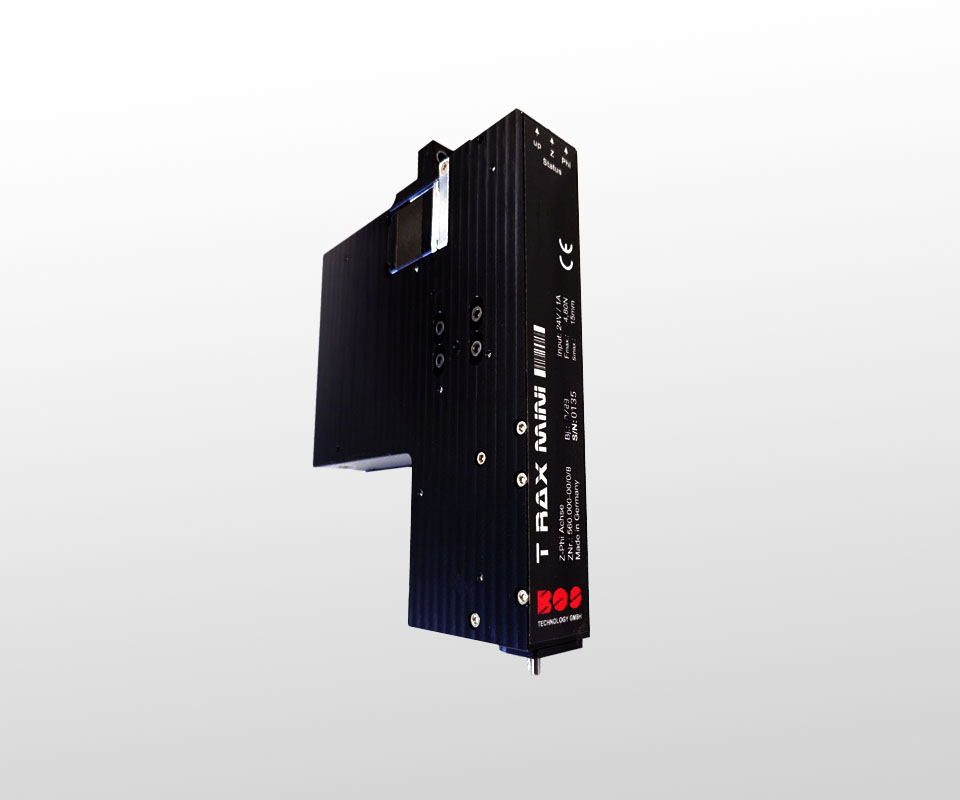

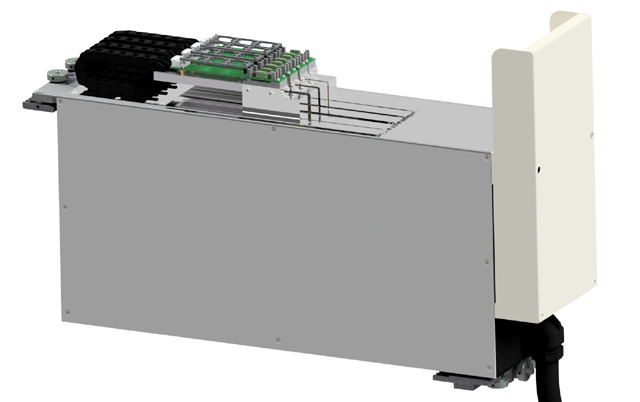

Measuring technology for analogue and digital elements for integration into checking equipment, tape and reel machines and programming equipment.

Highly skilled employees with many years of experience translate customer technologies into innovative system concepts. The specialized machines from BOS represents customer-specific systems for the automation of production processes that can see and feel, with 100% quality control built in.

The company's managers and its 30 staff have many years of experience in the development, design and construction of specialized machines.

BOS is established worldwide as a professional and dependable partner for the automation of production processes.

One of our greatest strengths is the flexible and customised development and composition of standardised modules to create powerful specialized equipment.

The emphasis of our work lies on the implementation of customer technologies in innovative, specialized equipment designed to automate production processes. The most popular product is the fully automated UNI-MX tape and reel machine, a checking and packaging machine with a flexible, modular construction that can be redeveloped and adapted to suit customers' requirements. Machinery for medical technology, environmental technology and safety technology rounds off our product portfolio. Each machine is compiled from standard modules that have been developed on a customer-specific basis.

© 2025 BOS Technology GmbH • All rights reserved